I thought it may be of interest to some readers to see some of the tools which are specific to the watchmaker. Some tools not presented on this page will be described when they are used for their specialized purpose. However, this page will describe general purpose tools that are used for various applications.

Throughout this site I point out the specific brand of tool which I used. I have no affiliation with any tool maker, and I do not sell or distribute tools. In most instances it is the only brand I have experience with, and I provide this for the readers' information and so that there will be little question as to what is being demonstrated or what was used.

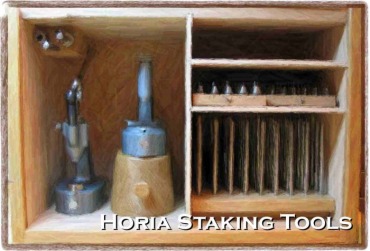

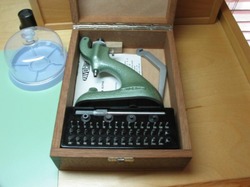

The Horia Staking and Jewelling Set

A tool set, referred to as a staking set, is the watchmakers' one-thousand-and-one-uses tool. It can be used for any number of different tasks, but principally it is for riveting (i.e. staking) components together or for driving components apart. The tool assures that these processes occur in an uprighted fashion, in that the staking punch is held vertically and the component is positioned directly below the punch in the horizontal. This setup is the basis for the countless other tasks that can be performed with it. The use of staking tools is covered in most texts. Archie Perkins covers the subject very thoroughly in volume 1 of Antique Watch Restoration.

Another closely related tool is the jewelling set, generally it operates on the same principal, but on a smaller scale. Its primary function is for pressing friction-fit jewels into place. The sets are supplied with special reamers which are of the dimensions necessary to produce a hole of the proper friction fit dimension. The anvil usually has a micrometer adjustment and is operated by a lever rather than with a hammer.

The set shown below is a combination staking and jewelling set and was made by the Swiss company, Horia. It is rather unique in that it is equipped with two anvils for the separate functions. Horia no longer manufactures this particular set, but offers a wide range of similar tools. I found this one second hand, and was not previously used but was not stored under the best conditions. However, it cleaned up well.

The wooden base is to allow the use of staking punches as stumps, by inserting them into the base and placing the anvil over top.

There is a pair of pin vises (primarily for using the reamers) and an adaptor for using them on either anvil.

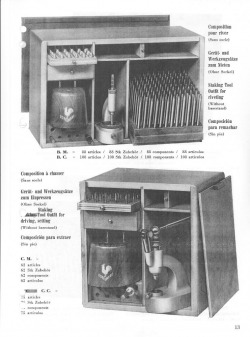

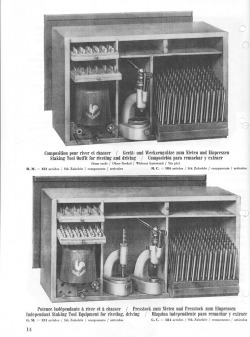

Here are copies of catalog pages for staking sets that I received from Horia a number of years ago. I have a slightly different version of their largest set on page 14. You can see descriptions of the various stakes and stumps and hints to their uses. Unfortunately the various other accessories are no longer available, such as the platforms for separating. These are useful for removing rollers and similar tasks.

Although the Horia set is quite nice, I have found the jewelling anvil a bit large for wristwatch jewelling. I happened across a "new-old-stock," Favorite brand jewelling tool. Another seemingly lucky find, it was still in the original packaging and VCI paper, etc. It is nearly identical to the Sietz or Bergeon brand jewelling tool sets that can currently found.

| Seitz Jewelling Tool (Bergeon 30300) | |

| File Size: | 351 kb |

| File Type: | |

The Depthing Tool

Two tools are shown below. They are approximately the same size, one is a Favorite brand (Swiss made) and the brass constructed one of an unknown maker. I generally prefer the brass one, but the Favorite has more rigid (thicker) runners.

Hammers

Files and Stones

I resisted using handles for a long time, however, I recently tried the Grobet screw-on type of handles, and they make filing much easier, giving much more control over the larger files. They are very simple to install, simple screw on, the handle locks on tight.

| Vallorbe Catalog of Files | |

| File Size: | 3780 kb |

| File Type: | |

Files with "safety" edges (non-cutting) can usually benefit from some additional smoothing on an India stone. This removes any burs left from manufacturing and ensure that it will be non-cutting when using the file.

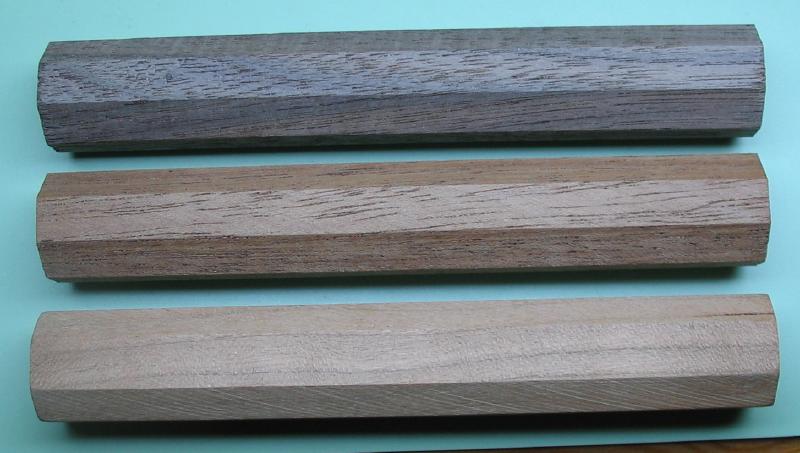

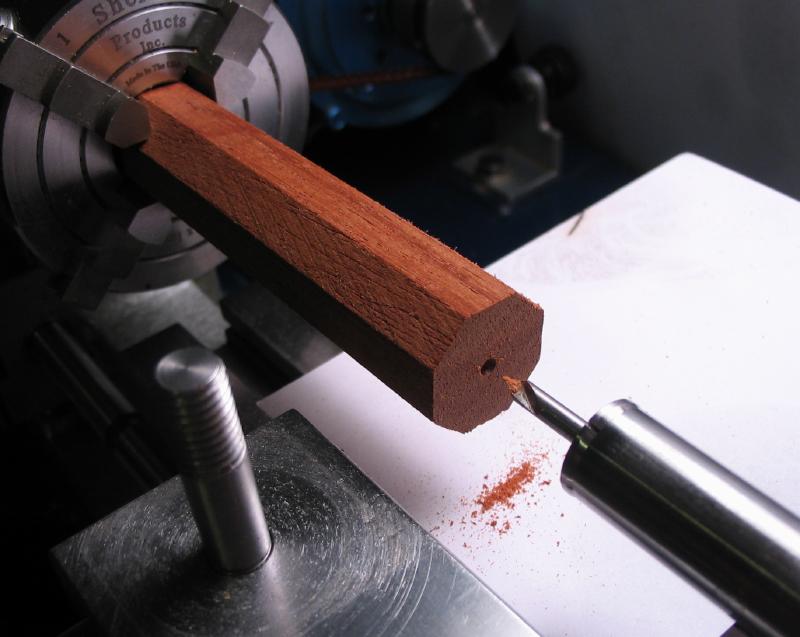

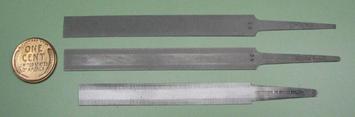

A "pillar" file is smaller than a "hand" file, and available in varying lengths as well as various widths. The pillar files shown are 4" long and were the shortest available and are the widest type of pillar file. These are from Grobet USA and are marked "made in Italy," and were available in three grades of cut, No. 0, 2, and 4. My No. 2 file appears to have some oxidation near the tang, but the set are otherwise well made. I made handles using 3/4 inch width wood "pen blanks." I used different species for each cut in order to more quickly identify the desired file and my selection included walnut, cherry, and mahogany. The safety edges of the files were smoothed on a India bench stone and the tangs deburred with a Arkansas stone file, especially the oxidized No. 2 file.

A roughly 3.5" length of wood 'pen blank' was mounted in the 4-jaw chuck, center-drilled, and with tailstock support, turned round. The end was reduced to about 12.1mm diameter for 1/2" in length to tightly fit a piece of brass tubing. A taper of about 4 degrees was turned, and a parting tool used to make a groove and the rear end chamfered. Corners were touched up with a file and the surfaces smoothed with 400 and 800 grit emery paper before finally parting off. Since the work was a little too long to drill on the lathe, this was carried out at the drill press with a 9/64" bit (the tip of the file tang measured as such) and then counter drilled 4.5mm to fit the top of the tang. The 1/2" brass tubing collar was driven on with a mallet, and then trimmed to match the length of the handle and polished while on the lathe with emery paper. The handle was already stained from my oily fingers, so after a light sanding to remove any last rag or burs, a good coating of mineral oil was applied to complete the process. The file was then installed by holding the file against the benchtop, tang up, and driving the handle on with a mallet.

10 inch hand file with purpleheart handle.

Screw head slotting files.

I found some unusual files when rifling through an second hand tool dealer's stand. They become other shapes in the arsenal. and included a small cut 6 equalling file, and rounding-off file (with safety), and an escape wheel rim finishing file (with safety).

Large Burnishing File

Related to metal files are stone files or slips. These are abrasive stones formed into various shapes and can be used to smooth parts or cutting tools. Shown are the assortment of slips included in a kit offered by Norton Abrasives and includes the basic shapes in both hard Arkansas and India oilstone. Composed of Ultra Fine Hard Arkansas

HF13, HF43, HF113, HF813, HF873, and Fine India FF14, FF44, FF114, FF214, FF724.

| Norton Abrasive Stone Catalog 2009 | |

| File Size: | 2561 kb |

| File Type: | |

Closely related to the stone slips above is a set of 'midget' stone files made from synthetic ruby, actually an engineered ceramic composed of aluminum and chromium oxides. The particle size is specified as 10 micron. They are often referred to as Degussit stones. They are manufactured in Mannheim, Germany, and I found them at Gesswein. Information on the midget files and material can be found here FRIALIT-DEGUSSIT. The set includes a pin vise for holding the smaller sizes, and 11 different stones in various shapes and sizes (see the web link above or section from their catalog below). The tiny size and very fine grit makes them very useful for getting into very tight spaces for final finishing.

| Degussit Fine Grinding Tools | |

| File Size: | 3470 kb |

| File Type: | |

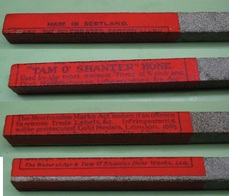

'Tam-O-Shanter' or 'Water-of-Ayr' stone

These stones are mentioned in various texts for scrubbing and polishing brass. They cannot be found anywhere for sale these days. I read that the mine (Dalmore) where the stone was sourced has closed and therefore no more cut stones are being produced. A fairly complete discussion can be found on Wikipedia. I found this one at the table of a tool dealer at the Cabin Fever Expo. It has obviously been waiting a while for me to find it.

This leads into the discussion of bench stones. There are some different opinions of the selection of bench stone that one should use, and it is a question of personal preference, I think. Shown is an Norton India oilstone (model IB-8), I do not know how these stones get their names, but India oilstone is a man-made Aluminum oxide stone, this one is a combination stone, having a coarse side and a fine side. The fine side is used for most sharpening jobs, gravers, cutting tools, screwdriver blades, etc.

For a very fine finish a hard Arkansas stone can be used. There are a lot of stones calling themselves 'hard Arkansas,' however they are not all the same. The type shown below (Norton HB4) is a natural stone, called Novaculite (mined in the Ouachita mountains of Arkansas, hence the name 'Arkansas'). It is very smooth, and imparts very little cutting action. Norton classifies it as 'ultra-fine.' Generally, I use the fine oilstone (above) and finish (if needed) with a couple strokes on the Novaculite to deburr the edges.

Other types of stones that can be found, and I find to be of lesser use; include soft Arkansas, the other type of so called 'hard Arkansas', and 'Black Arkansas.' The three below were a set of stones, the soft stone on the left cuts very fast and wears quickly, the middle stone is also fairly abrasive, and the black stone is quite smooth, but not as smooth as the Novaculite stone above. One can only experiment and find what gives the best results. I've tended to use the stones below for general purpose grinding tasks (stoning the burs off a piece of work, etc.)

While I am on the subject, another abrasive file that is useful for various tasks, such as sharpening carbide lathe cutting tools are diamond laps/files. Shown are the EZE-LAP diamond hone, and consist of plastic handles with 3/4" x 2" diamond grit pads of Superfine (1200), Fine (600), Medium (400), Coarse (250), and extra Coarse (150).

Piercing Saw (a.k.a Jeweler's saw)

| Vallorbe Saw Frame | |

| File Size: | 694 kb |

| File Type: | |

Hacksaws are useful for general stock preparation. A bandsaw or cut-off saw or some other mechanical means of sawing stock would be useful, but the simple, labor-intensive method is with a hacksaw.

Miscellaneous Tools

I will try to document various other tools that may or may not be familiar to someone outside the horological world; as I use them and have the camera handy or as I acquire them...

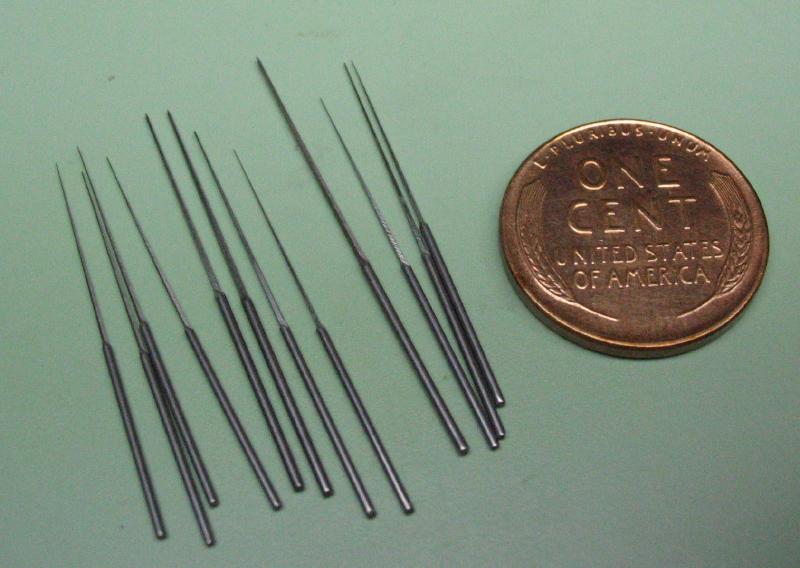

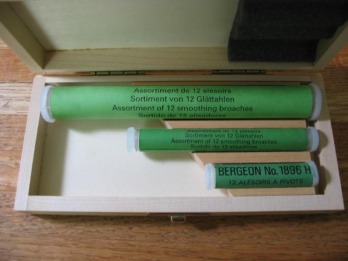

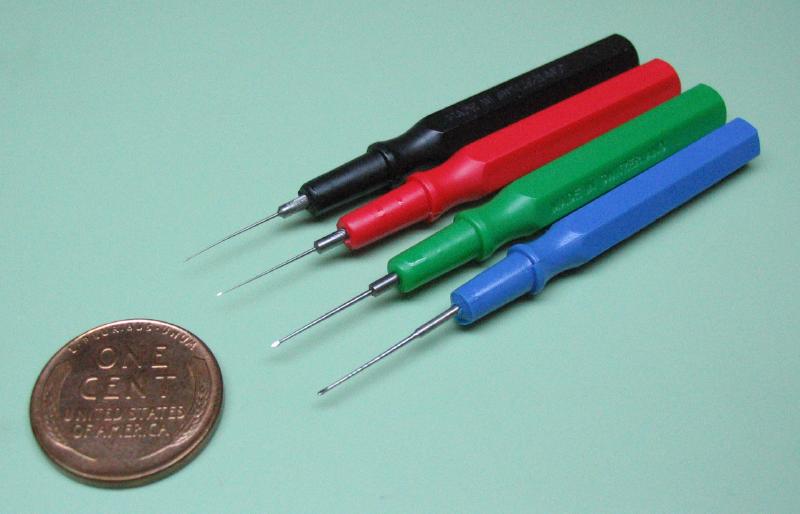

A collection of tools used quite frequently are cutting and smoothing broaches and pin vises. Broaches are used to open and finish holes. Pin vises are used repeatedly for numerous tasks, and a good quality set would be highly recommended.

Bergeon 30046 Assortment of Cutting Broaches

| Bergeon 30046 | |

| File Size: | 83 kb |

| File Type: | |

Bergeon 30075 Assortment of Smoothing Broaches

| Bergeon 30075 | |

| File Size: | 61 kb |

| File Type: | |

Bergeon 30026-A First Quality pin vises. These pin vises have two collets each (except the smallest one), which can be annoying when having to stop and disassemble the vise to change collets, but otherwise I've found this to be a great set and frequently used for holding small tools or work.

| Bergeon 30026a | |

| File Size: | 557 kb |

| File Type: | |

Grobet-Vallorbe Scraper, useful for removing burs or scraping metal edges.

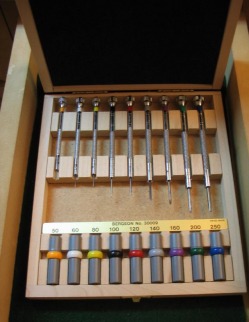

Screwdrivers, a good set of assorted screwdrivers is a basic necessity (shown is the nine sized set 30009). Some may conclude that an expensive set means they are perfect and will never need service. The blade of the screwdriver is made of tempered steel, and wear fairly quickly with use. They need to be touched up frequently on the bench stone to restore the shape. Regarding the shape of the blade; it seems to be a debated topic whether the shape should be hollow ground or wedge shaped. If the screws are handmade using a screwhead file to form the slot, a wedge shape screwdriver blade fits nicely. Also, the wedge shape is easily formed on an oilstone. See Daniels' "Watchmaking" figures 21 and 22 (1st Edition).

| Bergeon 30009 | |

| File Size: | 560 kb |

| File Type: | |

| |||||||

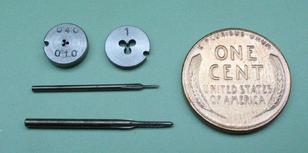

Taps and Dies

When I decided to take the plunge and purchase the required taps and dies (they are expensive), it happened that Bergeon was in the middle of either retooling/redesigning their dies or were in search of a new manufacturer. At first the various distributors simply told me that they were discontinued and no sets were available. Fearing the worst I called every distributor and ordered the various taps and dies individually as they were in stock until I had a complete set. I now see that they are again available, and at about twice the price!

| Bergeon Catalog of Taps & Dies | |

| File Size: | 215 kb |

| File Type: | |

For general toolmaking one will require larger sizes of taps and dies. For these there are a number of different makers from various countries. I can only recommend, as with any tool, that you purchase good quality, as it pays for itself in the end. A high quality American made brand is Greenfield, their full catalog can be downloaded from their site, it is fairly large. I made a excerpt below that contains the basic metric sizes. These too are quite expensive, but last for a very long time, especially in the home workshop. I purchased them as I needed them. Shown is 3mm x 0.5; 4mm x 0.7; 5mm x 0.8; and 6mm x 1.0. Also, at the bottom are the tap and die to form the threads found on collets and the drawbar of the watchmaker's lathe (this pair is not made by Greenfield).

| pages_from_greenfield_tap_and_die_exerpts.pdf | |

| File Size: | 609 kb |

| File Type: | |

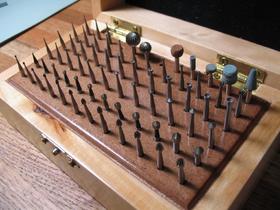

To countersink holes and round over the ends of pins, etc. a set of various jewelers burs will come in handy. These can be found from any jewelers tool distributor, and seemingly countless size and shape combinations exist. They are available in various grades of steel and carbide as well. Shown at the right is a selection of larger sized burs made by Dentsply Maillefer to shown some of the shapes that are available. The most useful seem to be cup burs for rounding over pins and spherical and 'setting' burs for countersinking holes. They can be used by hand while held in a pin vise or mounted in a spindle, such as the lathe, drill press, or flex shaft depending on the situation. They typically have a 3/32" diameter shank.

Poising tool. This was a used purchase, they are quite costly to buy new. This one is a Vigor-Bergeon No. 2802 and is essentially identical to the current Bergeon 2802 model. It is for testing the poise of balance wheel assemblies or any round object with an axle (e.g. tourbillon carriages). The bubble level can be placed onto the ruby jaws to set the tool level using the adjustable legs, and the jaws can be positioned to allow the pivots of the object to be poised to rest upon them. The object is tested by allowing it to spin and come to rest, it will tend to rest with the heaviest side down. The object is adjusted by whatever means appropriate (filing, chamfering, moving weight screws, etc) until the object will spin and comes to rest with no preference to a particular side. Like many watchmaking tasks, it is an expensive tool and seemingly over-complicated method of achieving a rather simple (but very critical) result. The testing process requires a very light touch (small, soft-haired brush or air bulb) with no other disturbances (air currents, table vibrations, etc) and lots of patience!

| Bergeon 2802ln | |

| File Size: | 68 kb |

| File Type: | |

Tweezers

Perhaps one of the most basic necessities on the watchmakers bench. They become so commonplace, that I almost forgot to mention them. If you have never handled a pair of finely made Swiss tweezers, then you will be surprised at the difference in sensitivity and quality from anything you will find at the drugstore. There is a wide variety of styles of tweezers and for each style there are various grades of steel. I will not go through them all, attached is the Dumont et Fils catalogue of watchmaking related tweezers and will be overwhelming even to the experienced. Below is a photo of my most used tweezers. I use a Dumont Dumostar No.2 for most general work, a No. 5 for very fine work, and somewhat recently purchased a pair of brass Peer-Vigor AM. The brass tweezers are quite nice and have become my most used. They do not scratch parts as easily and seem to grip small parts better than steel ones do. For anyone who has worked on watches, I am sure they are all too familiar with small screws shooting across the bench (or room) when pinched a little to tightly. (I have spent my own fair share of time on the floor looking for lost parts!)

| Dumont Catalogue Watchmaking | |

| File Size: | 1797 kb |

| File Type: | |

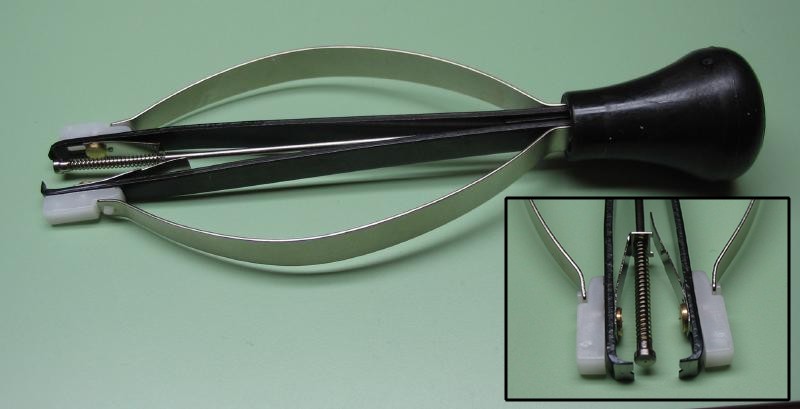

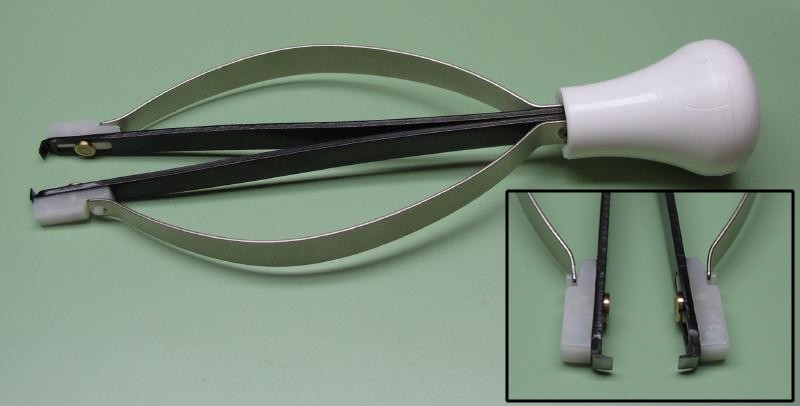

Hand Removal

Bergeon produces a series of specialized hand removers with special functions to suit the various types of hand pulling scenarios one is likely to encounter. The mechanism pulls the hand while simultaneously applying pressure to the dial face with the non-marring plastic feet. Shown are the Bergeon Presto models 1, 2, and 6. No.1 is a hand puller with a spring loaded retainer for securing the hand while prying it from its post. No.2 is a simple version for pulling larger sized hands, and is useful for pulling cannon pinions as well. The No.6 model is similar but a smaller size and useful for seconds hands.

| Bergeon Presto | |

| File Size: | 353 kb |

| File Type: | |

Metrology

Accurate and precise measuring is a basic need in the workshop, especially when making something. Of course, even in horology their are some who use the Imperial system (inches) and some who use metric. Watches are dominated by the metric system, but the ability to measure in both systems can be useful on occasion.

The two basic tools for measuring are the caliper and the micrometer. The caliper is quick to use and can measure depths and inside diameters in addition to basic outside diameters. The Starrett 120AM-150 caliper is accurate to 0.02mm, and in some instances this is sufficient. For higher resolution measurement of outside diameters, a micrometer is needed. The larger metric micrometer shown below is a Starrett V230MXRL (0-25mm) and is graduated to 0.002mm. A half-size micrometer (Starrett 232M, 0-13mm) can be handy for fitting into smaller spaces or provide more control when measuring small components. Also shown is a Mitutoyo micrometer (# 103-260) which measures in imperial units (down to 0.0001").

| Starrett Calipers | |

| File Size: | 478 kb |

| File Type: | |

| Starrett Micrometers | |

| File Size: | 734 kb |

| File Type: | |

There are four types of measurements that can be made with a caliper. I was aware of three and recently learned of the fourth, so thought it was worth sharing. These are demonstrated on a scrap mainspring barrel in the photos below, 1) outside diameter with the lower jaws, 2) inside diameter with the upper jaws, 3) depth with the extending rod, and 4) shoulder length using the front of the tool and the sliding carriage on the back of the tool. There is an extended base attachment for making depth measurements on larger work.

I purchased the caliper above as part of the "Student Tool Set" S903MZ produced by L.S. Starrett, who produce some very fine tools and instruments. This tool set includes an 11MH-6-4R combination square (shown below), C330-150 Flexible steel ruler (0.5mm graduations), 83A-6 solid nut divider (a little big for most watch work), an 117B center punch, and the "Starrett Book for Student Machinists."

A Douzieme gauge is useful for measuring thicknesses of objects that are otherwise difficult to measure using a caliper or micrometer. The name refers to a unit of measure that is 1/12th of a ligne, however, the gauge shown is graduated in 1/10th of a millimeter. This particular model has an adjustable point that can be reset to zero for certain applications.

| Starrett Tool Sets | |

| File Size: | 771 kb |

| File Type: | |

Heavy gauge, tempered steel rules. Starrett C635 Metric (0.5mm) and C616R Inch (32nd, 64th, 50th, and 100th).

| Starrett Precision Rules | |

| File Size: | 3458 kb |

| File Type: | |

Laying out lines onto metal is done with a scriber. Removable tips are easier to resharpen on the lathe, and can be stored protected within the handle.

Scribing circles, arcs, and radii is accomplished with dividers. These can be used to roughly measure distances or directly transfer a measure from an object or ruler to the work.

Another useful tool is a set of feeler gauges. These are great for just simple checks of small gaps and checking the progress of reducing the thickness of small parts.

When marking positions on metal, a prick punch and center punch is used.

Toolmaker's Bench Block

| Starrett 129 - Bench Block | |

| File Size: | 110 kb |

| File Type: | |

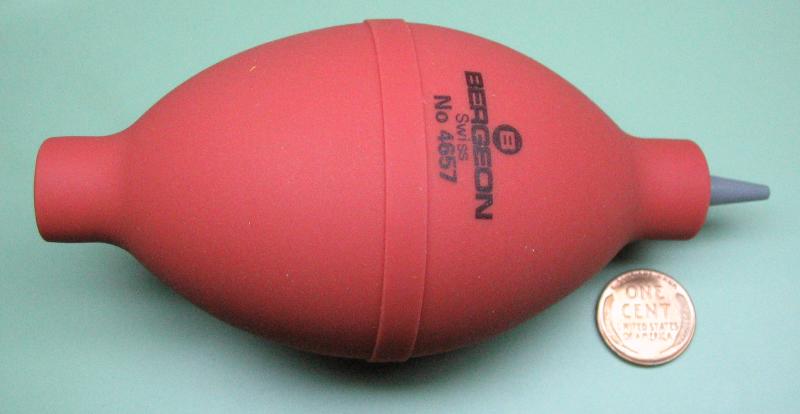

Compressed Air

A source of compressed air is very handy for removing dust or clearing out blind holes or any countless other purposes. The simplest is an air bulb or bellows if you prefer. Shown below is a brand new Bergeon 4657 that replaced a fairly well worn generic rubber air bulb. It was down graded for use around the lathe where clearing metal chips out of tight corners and holes is a regular need. Using it around the lathe also gets the air bulb quite dirty and decided a separate one dedicated to the assembly bench was in order.

Magnification

Choice of magnification is largely a personal matter. I will show what sorts of aids I use, however, I have yet to find an ideal solution, so it is an open ended discussion.

The first type of magnification is the sort most people would associate with watchmakers or jewelers. This is the traditional loupe. They are available in a variety of strengths and lens qualities. They are best suited to those who do not wear eyeglasses, so they are of limited advantage to myself. For quick inspections, holding the loupe in one hand, they are quite useful. One shown below is a Bausch & Lomb 10X Triple-Hastings loupe, and is good quality and a good strength for close inspections.

| Bausch & Lomb Catalog of Magnifiers | |

| File Size: | 1140 kb |

| File Type: | |

For the eyeglass wearer several options are available. Below is the Bergeon-Ary spectacle loupe which clamps to the eyeglass frame and has a hinged, traditional style loupe. This is a 5X loupe (others are available, including a removable 10X booster lens). The optics are quite nice, I regularly use this one for wristwatch work. If I were to buy it again or another one I would likely get a weaker power.

| Bergeon Catalog of Loupes | |

| File Size: | 546 kb |

| File Type: | |

Another Bausch & Lomb product suited for the eyeglass wearer is their "Classic Metal Eyeglass Loupe." They are available in a variety of strengths and either singles or doubles. Daniels recommends this type of loupe, in a doublet, in focal distances of 5 and 10 cm. The 3x/5x model has focal distances of 5.1 and 8.4 cm, this is closest I could find to Daniels recommendation (by my calculations his would be about 2.5x and 5x). The clamp is a simple type and works well with wire frame eyeglasses (a problem with some other type of similar loupes). An advantage of this arrangement is that the lenses can be combined to provide a stronger magnification.

The above type of loupe tends to get in the way, as it attaches to the side of the eyeglass frames. A center mounted assembly may be preferred, but will likely need to be made. The construction of the assembly below is detailed on another page. It uses two 25mm lenses, in focal lengths of 5cm (5X) and 10cm (2.5X).

For most general lathe work, I have been using a visor type magnifier. The OptiVISOR is a good quality product, using ground glass lenses. They are available with a variety of different strength lenses and are interchangeable. I chose the #3 lens, which is only 1.75x but has a focal length of 14 inches, so I can stand at a comfortable distance from the lathe. I added the OptiLOUPE auxillary lens, which adds an additional 2.5X, and is highly recommended. The visor aspect of it is great when working under an incandescent lamp over the lathe.

Cleaning

There are manual and automated methods of cleaning. Described here are the methods of cleaning by hand. The complete details of hand cleaning can be found in various texts, such as "Watch Repairers Manual" (H. Fried) or "Practical Watch Repair" (D. DeCarle). In general, solvent(s) are used to loosen and remove old lubricants and debris. This is assisted by brushing and rubbing with shaped pieces of wood. Obviously, this is the most laborious of methods, and any professional shop will be found to use more automated processes.

One confusing term found in various books is "benzine," in the U.S. the term is not used, and should not be confused with benzene (an excellent solvent but a potential carcinogen). It took some searching to determine that this refers to the petroleum distillate composed primarily of pentanes, hexanes and heptanes. This seems to be most commonly referred to as 'naptha.' Another solvent of use for cleaning is denatured alcohol, which is primarily methanol. Methanol has the usefulness of being water soluble as well. For degreasing of delicate parts, such as hairsprings, trichloroethylene is useful, and can be purchased from tools suppliers under the name "One-Dip." I store solvents in shallow Mason jars.

Removal of dirt and such can be easily done with various types of hand brushes. Sometimes referred to as Glasglow brushes, they are available in various grades of stiffness.

Solvents will leave a discoloration on the surface of metal if allowed to air dry. To prevent this, parts are dried in 'sawdust.' Coarsely granulated boxwood can be purchased from tool suppliers. I store the 'sawdust' in a small cigar box. After the parts are dried, the coarse 'sawdust' is easily blown away with an air bulb.

Other sundries useful in cleaning watch parts are 'pegwood,' 'pithwood,' and Rodico. Pegwood can be sharpened to various shaped points to get into pivot holes and other tight spots. Pithwood is a soft, almost malleable wood that sharp tools (such as tweezers and oilers) can be cleaned as well as watch parts, etc. Bergeon's Rodico is a tacky, 'silly putty' like substance that will remove debris and dust as well as fingerprints. Older texts describe the preparation of fresh bread dough for the same purpose. Rodico is apparently the modern, more stable Swiss equivalent. As the Rodico is soiled I progressively demote its use to more dirty applications. In the end I use it to remove emery residue from crevices while polishing.

| Rodico | |

| File Size: | 220 kb |

| File Type: | |

Pivot File & Burnisher

Hand tools

Lubricants

Horological lubricants can vary depending on country and personal preferences. I use both synthetic and natural, Swiss made lubricants. For a watch of the size described on this site, the following range of oils and greases manufactured by H. Moebius & Fils are described.

Microgliss D/5 - Mixture of mineral oil and neatsfootoil.

- Thick oil, recommended for barrel arbor and center wheel

Synt-A-Lube Art. 9010 - Mixture of synthetic hydrocarbons with ether

- Thin oil, recommended for remaining gear train, escape wheel, and balance staff

Synta-Visco-Lube Art. 9020 - Mixture of synthetic hydrocarbons with ether

- Similar to 9010, slightly thicker (more viscous), therefore for slower moving components

Art. 8200 - Mixture of mineral oils, vaselinic grease and neatsfootoil.

- grease recommended for mainsprings, winding and hand setting mechanisms.

Special Oil H.O. Art. 941 - Mixture of alkyl-aryl-monooleate and two C10-C13 di-esters

- recommended for escapement jewels, due to its adhesive properties

Oils are typically applied using a small needle. A variety of specially made applicators are available from manufacturers (i.e. Bergeon), and the most simple form is a set of needles in a range of diameters. The tip of the needle is somewhat flattened and made to a spade shape in order to hold a small drop of oil, which is then applied by simply touching the tip to the desired location. As described in some books, these applicators can be made relatively easily from wire. Before and after each drop of oil I poke the oiler into a piece of pith wood to clean it in order to prevent dirt getting in/onto the wearing surface or bearing.

A publication titled "The Practical Lubrication of Clocks and Watches" was, at least at some point, available for download on the BHI website, and can be found below. It is a concise introduction to lubricating watches with modern oils.

Below are the material safety data sheets for these lubricants which contains more details of their composition.

| The Practical Lubrication of Clocks and Watches | |

| File Size: | 3063 kb |

| File Type: | |

| Microgliss D5 | |

| File Size: | 1937 kb |

| File Type: | |

| Synt-a-Lube 9010 | |

| File Size: | 1833 kb |

| File Type: | |

| Synta-Visco-Lube 9020 | |

| File Size: | 1804 kb |

| File Type: | |

| Moebius 8200 | |

| File Size: | 1902 kb |

| File Type: | |

| Moebius 941 | |

| File Size: | 1923 kb |

| File Type: | |